HYUNDAI HEAVY INDUSTRIES

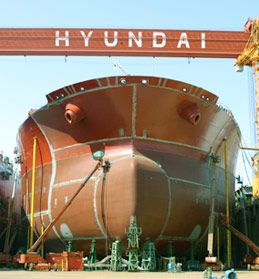

Hyundai Heavy Industries Co., Ltd. (HHI) had its ground-breaking ceremony in 1972 in Ulsan, a city located on the southeastern tip of the Korean peninsula. Immediately after the ground-breaking ceremony, HHI started building two 260,000 DWT VLCCs as well as its dry dock. Two years later HHI held a christening ceremony for its first two completed VLCCs.

In 1984, just 10 years after HHI delivered its first two VLCCs, HHI surpassed 10 million DWT in ship production. Since then, the shipyard has reached aggregate production milestones of 30 million DWT in 1991, 50 million DWT in 1997, and 100 million DWT in 2005, setting new world records in ship production. Today HHI accounts for approximately 15% of the global shipbuilding market.

As of the end of 2010, HHI had delivered more than 1,593 vessels to 258 different shipowners in 48 countries. When considering Japanese and European shipyards that are over 100 years old, HHI's unprecedented shipbuilding performance has rewritten world shipbuilding history.

Hyundai's Ulsan shipyard covers over 7,200,000 square meters. Workshops and facilities are arranged within this vast area to maximize the efficiency of shipyard operations. The roofed workshops cover an area of 1,600,000 square meters. HHI's facilities include nine dry docks of varying sizes, allowing HHI to build any type of vessel of any size.

Currently, Dry Docks #1 are allocated for building LNG Carriers. Dry Dock #3, HHI's largest dry dock with a 1 million DWT capacity, is reserved for the simultaneous construction of an assortment of ships.

The construction of naval ships and special purpose vessels is carried out at Dry Docks #6 & #7. Dry Dock # 9 has been specially designed to optimize the production of VLCCs.

Advanced Facilities

Hyundai's Ulsan shipyard is equipped with the most up-to-date facilities and equipment, including fully automated steel-cutting lines and an environmentally-friendly painting shop.

With a high level of automation and new production technologies including offline welding robots, indoor production of 40m long blocks, and a two-component proportioning system in painting, HHI offers a number of advantages: greater productivity gains, reduced building times, and above all, superb ship quality.

- Afloat Repairs

- Sliplift

- Floating Dock

- Graving Dock

- 0-100m

- 101-200m

- 201-300m

- 301m & over

- Quay

Advanced Search : Find Shipyards by Region and Ship's size

Advanced Search : Find Shipyards by Region and Ship's size